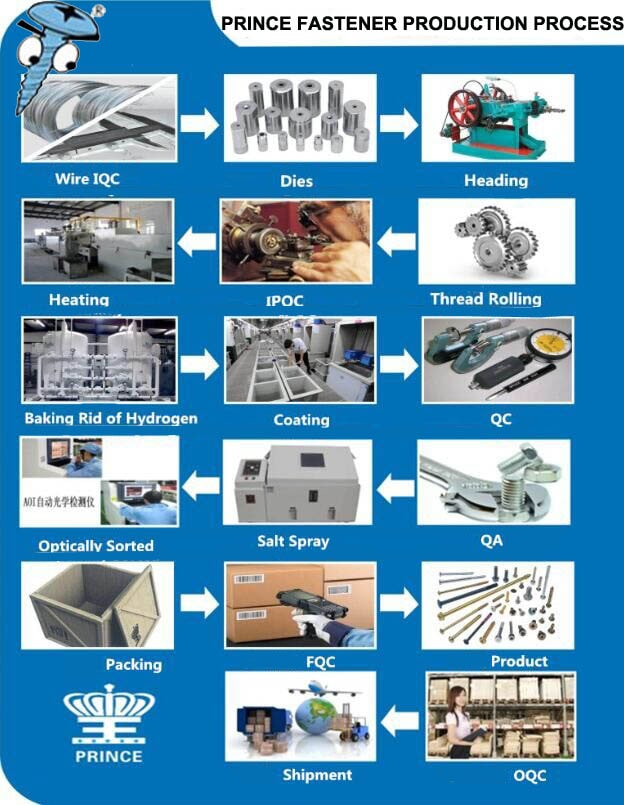

Basic concepts of Prince Fastener screw production

1、Prince Fastener Manufacturing screw can be divided into: cold heading, hot machining (turning, milling, etc.)

2、Cold heading is the use of plastic metal, by using cold mechanical pressure or drawing, reaches the metal solid deformation of.

3、Hot upsetting is the material after heating and pressure processing make the shape of the material to meet the

designrequirements.

4、Prince Fastener Machining is a small batch of special or special bolts of the six corners of the head is turned into after the milling.

5、 Screw bolt thread: mechanical and manual threading, similar to die.

6、 Milling tail: generally completed by the end of the Prince Fastener cutting machine.

7、 The difference between cold and hot upset: cold heading bolts` surface are more beautiful, dozen red bolt surface oxide skindoes not look good; cold heading high production is efficiency; general Prince Fastener M24 bolts will need to play red;

Analysis of the causes of the phenomenon and the causes of the forming process

1、Eccentric: two red and improper installation and adjustment machine.

2、Minow: a poor installation and improper Prince Fastener adjustment machine at.

3、Head is not round: the choice of a die or a punch forming is not enough.

4、Play the mode of crack: crack or die R angle, so that the model is hit by the two collision.

5、Head double: bad punch.

6、Flash: a bad, punching molding is mainly between punch and die hole clearance is too large or too short by red bars.

7、Crack angle: the punch needle burst or two punch and punch is not heavy.

8、Head cracking: material, or a die using error (such as pan head Hexagon washer head of a die), and lubricating oil.

Analysis of adverse phenomena and causes of common rolling

1、Processing crack: tooth plate and adjust the Prince Fastener old machine.

2、Blunt tail: the machine is not properly adjusted, the tooth plate is too old.

3、Crooked tail: the control screw on the seat board seat is too tight.

4、Tail: tooth wear plate and improper adjustment machine.