Prince Fastener:Types and Uses of Drywall Screws

Today, Prince Fastener recommends the story behind the development of NIO battery replacement bolts, including: Why did you choose the bolt solution from many structures? How do the bolts set various parameters (including how to distribute, how much to tighten), and which designs to use to make the bolts more stable?

Before the engineer’s sharing begins, first of all, we invite Netease’s popular science IP – “The Answer is as follows” to reveal the past and present of threaded fasteners for everyone:

On December 10, NIO’s 700th power station in China was delivered for use.

Not long ago, as the world’s first power exchange export project, NIO completed the layout of the first overseas power exchange in Norway.

Since the first battery swap station was launched, NIO has provided users with more than 5 million battery swaps, with a maximum of 20,000 battery swaps in a single day.

After 20,000 full-charged trips, more than 20,000 power battery loading and unloading operations are behind it, which is a severe test for the power exchange mechanism’s reliability, safety, and convenience.

How does the battery of hundreds of kilograms complete the rapid loading and unloading? Can the fasteners of the battery withstand such frequent loading and unloading? In this issue of Tech Talk, we have invited Miro. Yuan, a fastener engineer for NIO’s vehicle engineering, to share with you the story behind the development of NIO’s battery replacement bolts.

Among the many connection solutions, why do the bolts stand out?

The power exchange mechanism connecting the battery and the body is important for realizing the power exchange function. Every power exchange is inseparable from this key mechanism.

At the same time, the connection between the battery and the body is the top priority, and there can be no mistakes; for this reason, the engineering team established three principles from the direction of safety, quality, and experience at the beginning of the research and development: Based on these threeprinciples, the engineering team The following three goals were identified:

1. Reliability: The whole vehicle normally runs over the entire life cycle, and the power battery does not loosen. Even under the impact of 50g horizontally/vertically (equivalent to 50 times the force of gravity on the stressed object), the battery will not be released from the storm. Body disengages.

2. Convenience: battery replacement can be completed in a few minutes.

3. Durability: 3000 times of safe loading and unloading and reliable power exchange for millions of kilometers.

Friends who have a certain understanding of the machinery industry should find that these three attributes are almost contradictory – to improve reliability, you must tighten, and the tighter the tightening, the more convenient the next disassembly; and to improve the convenience of disassembly, then It will affect reliability, and at the same time, repeated loading and unloading will easily cause fatigue of parts and reduce durability.

This set of contradictions is even more prominent in large-size, large-capacity, and high-quality battery packs.

However, the simpler the mechanical system in industrial manufacturing, the more reliable it is. To this end, the engineering team tried various mainstream connection schemes, such as electromagnetic relays, latch structures, snap-on structures, etc., and even studied the missile connection device (clamping structure). After careful consideration of tightness, reliability, durability, layout space, cost, etc., the bolt structure finally became the starting point for the research and development of battery replacement fasteners.

How is the “absurd” idea realized? Many creative inventions originate from an “absurd” idea.

Bolting on for thousands of quick battery changes is no exception.

We consulted many well-known fastener companies in the industry. Many experts heard that it is impossible to make a bolt structure loaded and unloaded thousands of times.

Because the characteristic of the bolt structure is that it is fastened but cannot be used repeatedly, the bolt structure that can be loaded and unloaded twenty times in the industry is very impressive, not to mention thousands of times.

After determining the bolt connection scheme, the number and location of the connection points of the battery pack need to be resolved first, which is closely related to the safety of the battery connection, the reliability and efficiency of the battery replacement durability, and this, in turn, needs to analyze the force of the bolt connection first.

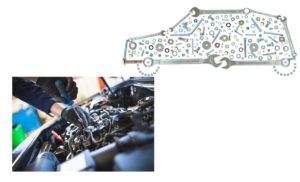

The general stress of bolted connection can be roughly divided into the axial load, lateral load, bending moment, and torsional moment. If the design is unreasonable, the clamped parts will have failure modes such as separation, warping, slippage, and loosening. According to the force analysis of the bolt structure, combined with the spatial system of the body and the battery pack, the engineering team initially designed bolt structure schemes with different layouts and specifications and preliminarily determined the preload force.

Afterward, the engineering team conducted multiple rounds of CAE (Computer-Aided Engineering) simulation tests in terms of strength, stiffness, vibration fatigue, and slippage to analyze the stress conditions of bolts structures with different arrangements under dozens of working conditions.

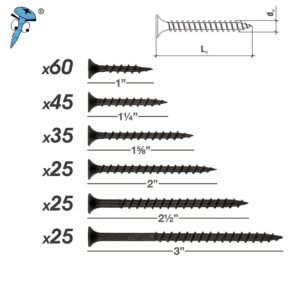

Through the combination of multiple rounds of CAE simulation analysis and theoretical calculation, taking into account the requirements of space layout, the engineering team determined the layout and specification scheme of the bolt structure-the power battery of NIO vehicles is equipped with 8 M18 and 2 M10, a total of 10 bolts. A single M18 bolt can achieve a locking force of 3 tons, which more effectively ensures the connection between the power battery and the body.

To make the bolt tightness meet the requirements and prolong the life as much as possible, we study the aspects of strength, hardness, coating, friction coefficient, etc., and find a suitable torque value according to the specification and clamping force of the bolt. First, engineers calculated the initial tightening torque from theoretical calculations. After determining the theoretical value, the engineering team obtained the most balanced torque value through repeated verification of 600,000+ times of component-level durability tests.

It passed 10+ times of system-level vibration shock and 60,000+ times of vehicle-level durability. The test has increased the safe use of the bolt to a breakthrough value of 3,000 times. How do you make the bolts better and looser? The engineering team created a double insurance – anti-loosening mechanism for the replacement bolts to enhance tightness and safety further.

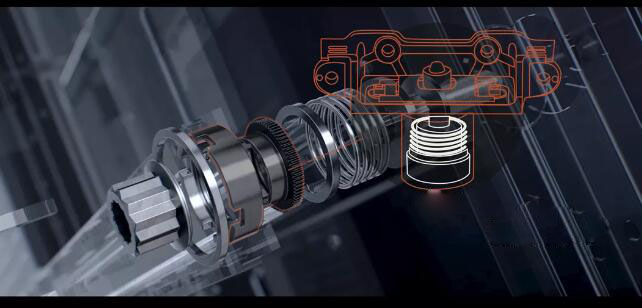

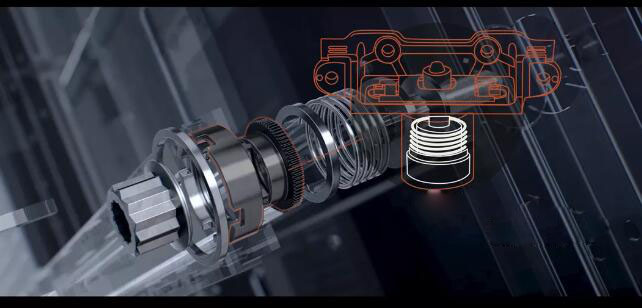

By studying the friction and anti-loosening methods of mechanical structures such as wedges, spring washers, double nuts, and stop washers, and through continuous verification and iteration, the reverse-threaded ring gear structure is applied to the power exchange bolt, and its tail is firmly clamped live.

When the bolt loosens, the reverse-threaded ring gear locks in reverse, allowing the bolts and nuts to tighten together.

To better absorb and eliminate the tolerance between different bodies, different battery packs, and different power exchange stations, and make the matching of bolts and nuts more smoothly, the nut also adopts an innovative structure – a floating space of ±4mm is reserved around the nut so that the position of different bolts can be better matched during the power exchange process. The floating nut is also firmly locked when the power exchange is completed. Bayobolt, the idea of subverting the industry more firmly, more reliably, and insisting on breaking the limit, this is what we think and work hard, we also gave this technology a nice name, Bayobolt–the first half of Bayonet (bayonet) The combination of Bayo and Bolt (bolt) means that this power exchange bolt is as elegant, accurate, firm and reliable as a bayonet.

From the debut of the first power exchange station to the launch of the BaaS battery rental service to the launch of the flexible battery upgrade plan, power exchange is the basis of all this.

One of the core physical foundations of battery swapping is Bayobolt. The underlying foundation determines the superstructure, and more research and development, especially the innovation and breakthrough of basic technology, can bring better products and experiences. Today, NIO has accumulated more than 4,400 patents and patent applications worldwide, including more than 1,400 patents related to battery replacement. We will continue to work hard on innovation, research, and development to bring better bolts production and experiences to users.