Prince Fastener:7 ideas to judge the management level of fastener manufacturer

Enterprise operation is an extensive system, and all links are closely related and affect each other. We can see the subtleties of production-oriented enterprises through any details of the scene. The root cause of any significant problem can be found on the spot. Even if you are looking at the flowers for a limited time, as long as you focus on the key points, you can fully grasp the critical information about the factory’s operation. The following will discuss how to conduct on-site observation with the macro system and management details.

01

Live atmosphere

You can first see the most real employees’ mental outlook at the scene. The employees with high morale and the sloppy and indifferent employees will be in sharp contrast. Talking a few words with the workers on-site can also make an important first impression from the worker’s facial expressions and body language. These directly reflect the worker’s mood and satisfaction with the fastener factory. In a factory I visited, cheerful music played in most of the workshops. At first glance, the workers were very enthusiastic about labor. Working in such a relaxed and pleasant environment is relatively more efficient, and the quality of the products will also make people happy. More confident.

When walking around the fastener supplier, you can observe whether there is uneven busyness. For example, when the machine is automatically processing, workers are idle for a long time, or workers at some workstations are waiting for materials for a long time. This phenomenon shows that the factory lacks lean management, and the utilization rate of personnel is low. Idle employees will also affect the working atmosphere of others. As a result, the overall work efficiency is low, and the cost is higher.

You should pay attention to whether there is sufficient light in the workshop, whether the air circulation is smooth, whether there is a peculiar smell on-site, whether there is too much noise, and whether the workshop is clean because these will also directly affect the mood of the workers, thereby affecting the production efficiency and product quality. It’s hard to imagine a factory where the atmosphere is lazy, low, and indifferent, and employees or resentful or idle factories can make good products and create benefits.

02

Space utilization and layout

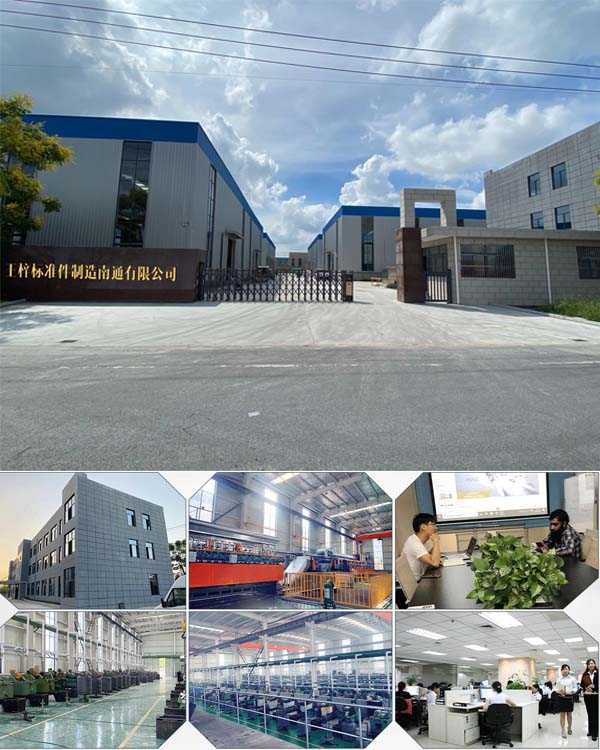

Many factories in China are very happy. The bigger the production workshop, the better. As a result, the utilization rate is often low, and the equipment and process layout are scattered. In addition to wasting space, materials are also carried out in the factory. Most factories in developed countries look less spectacular, or even a little cramped, but have high space utilization and high circulation efficiency.

Transport means taking up space, is expensive to operate and encourages unnecessary material movement. I saw a lot of electric forklifts and manual forklifts in a customer factory busy shuttling, but there is a lot of unnecessary handling. For example, the same batch of parts is moved from area A to area B after processing, moved back to area A for subsequent processing, moved to area C for processing, and finally moved back to area B. The waste of handling is simply extreme.

In principle, the production materials used on the day should be stored along the production line rather than separated in several inventory areas. The tools and tooling should be placed as close to the machine as possible. The layout of the factory should ensure the smooth flow of products and try to avoid any partitions. Suppose you see a long material handling distance, repeated handling routes, or many handling times in a factory. In that case, the layout is unreasonable, and space utilization is not ideal. It also shows that the production lines are not assembled as much as possible.

03

Field standardization

Standards are the best state and uniform performance reference. There is no way to implement without standards, and there is no focus for improvement. Therefore, there should be many standards on the production site, including operation and quality standards, 5S and safety standards, operation and maintenance standards, process and rework standards, safety stock standards, etc.

Many factories have SOPs (standardized operating procedures). We can observe whether these standards have missing items, whether they are easy to implement, and whether breakpoints are in the middle. Check that what is written, said, and done is consistent and that quality control points are highlighted with a prominent logo or color.

By observing the specific operation process of different employees in the same process, you can determine whether there are differences, including the sequence of actions, the intensity of operations, and whether there are omissions. If there is a difference, the staff lacks standardized operation training, and the possibility of product variation is significantly increased. For example, when I visited a supplier factory, I found that different workers locked the four screws in a separate order, and there was no standard torque reference. It is all based on feeling. Some workers will lock twice, while others will only close it once. Quality complaints of falling off or locking too tightly on one side, causing the other side to stick up.

04

Quality control

On-site observation should focus on how the workshop handles defective products. A good factory will expose problems, not cover up harmful and scrap effects. For example, using light to focus the scrap or highlighting it with a red tag, it is immediately possible to know if the fraction is increasing or if a section of the production process is producing defective products.

I saw a lot of defective products in the corner of a factory, from the dust on it that had accumulated for quite a long time, but there was no sign to explain the cause of the defect and the problem. Asked the on-site workers, the answer was that those things were several months old, no one knew what the problem was, and no one dealt with it. Asked how to deal with defective products, the answer is that there is a particular person to rework, and no one goes to the root of the defect. Who would dare to cooperate with a factory with such chaotic quality management?

The traceability of work-in-progress and semi-finished products can also be easily seen on site. Each component has a card or a document to follow the circulation in a good factory, indicating the source, processing personnel, equipment used, and other information. Problems found in any fastener process can be easily traced back to the head, which is also convenient for improvement.

The on-site can judge the fineness of the quality management of the products by the degree of protection of the parts by the workers. For example, in a motor factory, I saw the rotors are randomly placed on the concrete floor without any protective measures. The quality of such a finished motor can be imagined. On the other hand, the stator is placed vertically on the wooden workbench, and the workers are reshaping the upper part.

By observing the quantity and proportion of defective products, it is also possible to preliminarily judge whether the quality control process of a factory is qualified. For example, when I visited a supplier around noon, I found more than 20 non-conforming products piled up at the end of the finished product line. After asking the workers, the average output of this assembly line is 1,000 pieces per day. Based on this, it is estimated that there are about 50 pieces of defective products per day, and the lousy product rate is as high as 5%. This shows that there are a lot of quality problems in the previous processes. Quality control is weak, and the cost of lousy manufacturing must be high.

05

Visualize

Visual management is the basis of many advanced management methods, and it is an intuitive communication of the management level of a production enterprise. In a well-managed factory, visualization tools are everywhere, including workplace organization and standardization, visualization of result indicators, visualization of everyday work, visualization of control indicators, visualization of automatic error prevention and correction, alarm mechanism, etc. Therefore, when visiting, you should pay attention to looking for various visualization tools.

Visual management kanban can be divided into static and dynamic management kanban. The static kanban mainly conveys the long-term management concept of the organization. The dynamic kanban is the management information that managers need to grasp and can better reflect the management level and ability.

5S is the embodiment of on-site organization and standardization and is the underlying application of visualization. However, due to various reasons, most Chinese enterprises have entered a misunderstanding in 5S management. For example, in a large motor manufacturing factory, the production workshop is almost spotless at first glance. All the floors are painted with beautiful paint, and all kinds of visual lines and signs are well done, but there is only a lack of safety warning signs. If the road surface is too smooth, the friction force is insufficient, people will slip when walking on it, and the trolley and forklift may also fall. This superficial effort is made well, but there are still many security risks.

06

Tool equipment status

In a good factory, the equipment is clean and well maintained, and information about the kit is readily available and up-to-date. Although the various lathes are not very advanced in the machine shop of a foundry or even have a long history, they are all running in good condition. I saw a card prominently affixed to the side of each machine that recorded the model of the equipment, date of purchase, price, supplier, repair records, maintenance records, and more. In addition, the daily check sheets are also recorded very wholly. Some check sheets record the hidden dangers discovered by the operators and the signatures and treatment plans of the equipment department. This shows that equipment management and maintenance have formed a benign system.

I saw a large vacuum dipping machine waiting for repair in another factory. It is said that the sealing rubber ring is aging and needs to be replaced, but the accessories will not be in place for a month. There is no maintenance record on this fastener production equipment. Although there is a daily inspection list, such wearing parts are not found until they are seriously aged and cannot be used, indicating that the inspection is not in place or perfunctory. The failure of this equipment could have generated an early warning and made corresponding preparations so as not to cause a one-month shutdown, which would seriously affect the production and delivery.

Employees can also be informed whether operators and product developers are involved in equipment purchase decisions in the field. Frontline workers and those involved in product development and production know best about the pros and cons of new equipment and the actual needs of the production line. Unfortunately, in many factories, equipment purchases are decided by the senior management or the equipment department, and the opinions of frontline personnel are rarely consulted, resulting in a large number of follow-up problems.

07

Precautions for on-site observation

On-site observation is the most direct method to find problems. Most of the issues will be manifested on the spot, and a preliminary assessment of the factory can be made quickly, which can be traced back to the source and can also reduce the blindness of a lot of work. This article discusses only a small part of the many contents of on-site observation. There are many ways and methods of on-site observation and different focus points, but the basic principles and matters needing attention are the same.

1) You can’t look at the scene with tinted glasses, and you can’t go to the stage to find evidence with a conclusion, which is often biased.

2) You can’t just look at the surface of the scene; you need to check whether what you say, write, and do is consistent, and you need to ask a few more whys.

3) Look at the macroscopic and microscopic perspectives simultaneously, focus on the details in the way of shrinking, and look at the whole in the form of an opening.

4) Try not to take notes, which will affect the continuity of observation and thinking and make on-site personnel nervous.