Prince Fastener:Fastener production process and crafts– Pick fastener package

The final inspection and selection of fasteners is the last confirmation of all the work in the previous sequence, and it is also the previous check. This process is followed by packaging and storage.

Fastener manufacturers usually manually select defects such as effusion and bumps; optical screening machines detect and select defects such as size, no thread, and oblique teeth.

Prince Fastener make the sixth article in the series of articles on fastener production technology, introduces the inspection content, personnel requirements, equipment principles, and packaging specifications involved in the final inspection process in fastener production.

01

Final inspection of fasteners

1. Identification check:

The imprint of the code is clear and correct, and the location is accurate.

2. Visual inspection:

1) The surface is clean and free of burrs, oil stains, other impurities, and rust;

2) concave deflation caused by mechanical damage;

3) Electroplating or coating effusion;

4) Color difference, blistering, and falling off caused by poor electroplating or coating;

5) There are cracks on the surface.

3. Thread defect inspection:

Omitting the rubbing or tapping process makes the parts have no teeth, bad teeth such as oblique teeth or rotten teeth, and thread bumping and deformation.

4. Screw head inspection:

There should be no adverse phenomena like a headshot, head deviation, cross point deviation, and pressure scars.

5. Bolt assembly or nut assembly:

Leakage gaskets, multiple gaskets, and wrong gaskets.

6. Mixing:

Fasteners of similar sizes, grades, and finishes are mixed.

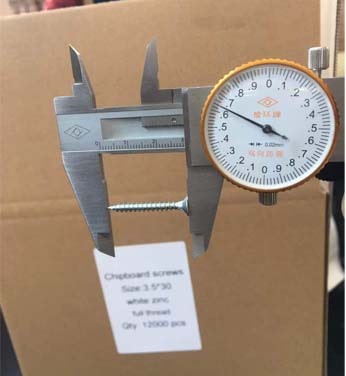

7. Size detection:

Thread diameter, thread lead-in length, pitch, and the corresponding thread gauge are used to detect.

8. Performance testing:

Hardness, breaking torque inspection, hydrogen flooding inspection, salt spray test—most of these tests are completed in the laboratory, and this article will not repeat them.

02

Manual selection detection

For fasteners produced in small batches, large fasteners, and special-shaped fasteners, the advantages of manual inspection cannot be replaced by machines.

1) Manual inspection tools:

Magnifying glass, digital caliper, digital micrometer, feeler gauge, thread gauge, and unique inspection tool.

2) Manual inspection conditions:

a. Light source of inspection site: 300–400LUX or under natural light

b. Inspection distance: about 30cm

c. Time: Visually stay for 3-5 seconds

d. Inspection angle: the product is at an angle of 45°-90° with the eyes

3) Manual selection process:

An a. Arrange the products: neatly stack them on the operating table, and protect them from falling to the ground.

b. Use special inspection tools to detect relevant parameters and select unqualified products.

c. Carry out 100% visual inspection of the products, check and select unqualified products,

d. Use a magnifying glass to conduct a thread appearance check and select unqualified products.

4) Notes on manual selection:

a. Pickers need to wear white cotton gloves or finger cots.

b. Prepare baskets of different colors for good and bad products.

c. Before and after selecting products, ensure that the work surface and floor are clean to prevent mixing.

d. When the whole work section is not completed, it is not allowed to add the product again to avoid the phenomenon of mixing.

e. Suspicious items on the ground shall be discarded.

f. Defective products should be placed in the material box and material box of the specified color and finally designated for scrap treatment.

g. Reworked products must have special processing procedures.

03

Optical image screening machine detection screening

The optical image screening machine is mainly used to detect and screen the appearance size and defects and automatically screen to distinguish good and bad products.

Many factories use optical screening machines to replace manual quality inspection.

Optical image screening machine, suitable for M3–M20 screws, nuts, bolts, washers, fasteners, and other fasteners that can be placed stably. The detection speed is as high as 1200 pieces per minute, and the accuracy is as high as ±0.001mm. In addition, it can be done that the screw teeth will not be damaged during the detection process.

Manual inspection of appearance and dimensional quality is required. However, manual visual inspection for a long time results in low product inspection efficiency and low accuracy due to eye fatigue. Using machine vision instead of artificial vision can significantly improve production efficiency and inspection accuracy and reduce labor costs.

The optical screening machine uses a CCD camera to convert the detected target into an image signal. First, it transforms it into a digital signal according to the pixel distribution, brightness, color, and other information. Then, the image processing system performs various operations on these signals to extract the characteristics of the target, such as area, quantity, position, length, and then output the results according to the preset allowable degree and other conditions, including multi-section height, multi-section width, broken needle, plug hole, invalid tooth length (lower neck tooth height), tooth bottom diameter, outer tooth diameter, dental tools, oblique teeth, bad teeth rolling, screw length, whether the head is plated or not, whether there is chamfering, plug holes, eccentricity, missing teeth, etc., thus realizing the automatic detection and identification function.

04

Fastener hardness eddy current screening machine testing and screening

Eddy’s current testing is a non-destructive testing method based on the principle of electromagnetic induction. It is suitable for conducting materials. When a product part is placed in an alternating magnetic field, an induced current exists in the region; an eddy current is generated.

Due to the change of various factors of the part itself (such as electrical conductivity, magnetic permeability, hardness, material, defects, etc.), the induced current will change, and this change can be fully applied to the detection of fasteners.

Fastener hardness eddy current screening machine is suitable for fast screening of fastener mixture, hardness deviation, thread missing, and considerable crack damage.

The system includes testing instruments, testing probe, mechanical, electrical, and four parts. Realize automatic defect detection, automatic sorting, and automatic alarm.

05

Machine Screening Considerations

a. According to the size of the product, adjust the vibrating plate and the unloading track.

b. The required value to ensure the vibration frequency of the vibrating plate.

c. Pay attention to thread protection when the product falls into the barrel.

d. The channel from the discharge port to the receiving box ensures that the material does not fall outside.

e. When replacing the screening product, clean the vibrating plate, material tracking, and ground to avoid mixing.

06

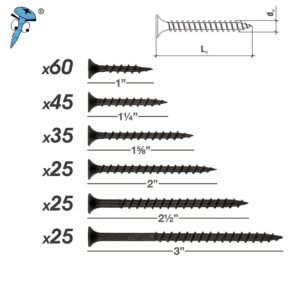

Fastener Packaging

1. Pack the material according to customer requirements.

Ensure that the printed graphics and text on the product label are clear and correct.

2. Only one product can go to the packaging table for packaging each time. It is strictly forbidden to pack two products with similar specifications or shapes simultaneously. The packaging table must be cleaned before packaging. The specific packaging methods and steps are as follows:

a. Choose whether to use a packaging machine according to the parts and choose the appropriate plastic bag size according to the features and the number of bags.

b. Prepare parts, cartons, balers, scales, and other tools to be packaged. Confirm the packing quantity per carton.

c. Lay the plastic bags of the corresponding specifications in the carton, put the parts into the plastic bags according to the specified number, and tie the openings. At the same time, set the inner label on the plastic bag.

d. Close the lid and stick the batch label on the left side of the box.

e. If there is a gap in the plastic packaging bag in the box, it should be filled with foam paper to ensure the quality of the product during transportation.

f. After sealing with sealing tape, put it on the automatic baler and use the baling video to make four crosses.

g. Place the full box neatly on the wooden pallet. It is required that the parts are placed from bottom to top, from heavy to light, and from large to small. The label on the outer box of the box is facing the outside. When mixing parts, the exact details must be placed together in the same layer. The number of stacked layers is 3, and the pallet bearing weight is less than or equal to 1000Kg.