Prince Fastener:Fastener production process and crafts– Surface Treatment

Material surface treatment is a process method to artificially form a surface layer with different mechanical, physical and chemical properties of the substrate on the surface of the substrate material. The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration or other special functions of the product.

Almost all fasteners require surface treatment before they can be used. Good corrosion resistance is the most basic requirement for surface treatment of fasteners. The surface-treated coating must be firmly attached and cannot fall off during installation and removal. For threaded fasteners, the coating must be thin enough so that the threads can still be screwed together after plating.

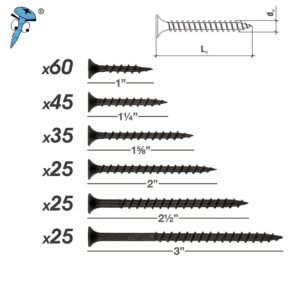

Prince Fastener make the fifth article in the series of articles on fastener production technology, explaining the concept and definition of surface treatment technology used in fastener production; Craft provides a contrasting picture of the product.

01

Classification of fastener surface treatment processes

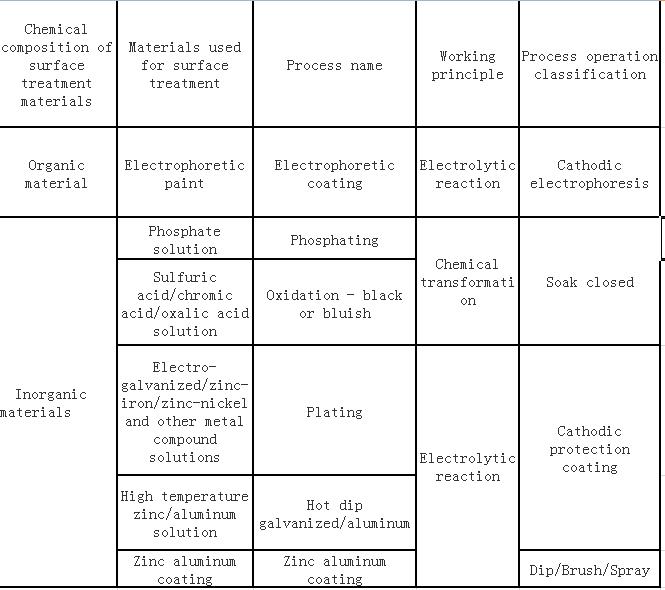

The surface treatment of fasteners has different names according to different classification standards:

Below, the various fastener surface treatment processes in the above table are summarized, which can be divided into two categories: surface conversion coating technology and surface coating technology.

02

Surface Conversion Coating Technology of Fasteners

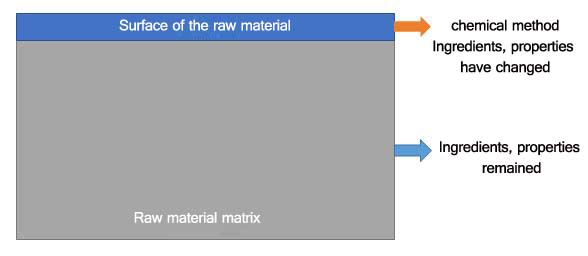

The surface conversion coating technology is a technology that chemically reacts the additive material with the substrate to form a conversion coating.

Phosphating and blackening both belong to the formation of conversion coatings on fastener substrates.

The schematic diagram of the structure principle of the surface conversion coating is as follows:

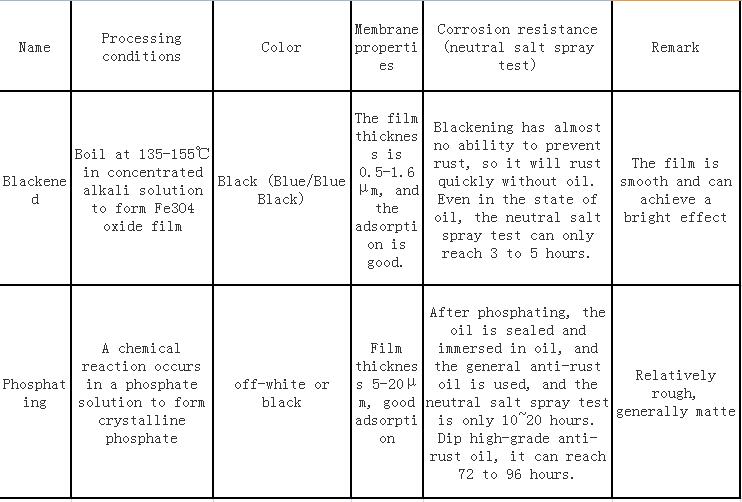

- Blackening is a common method of chemical surface treatment, also known as boiling black or bluing. The workpiece is often immersed in a strong oxidizing chemical solution, and after a certain period of time, a beautiful, dense and rust-proof black iron oxide film is formed on the surface. Blackening process: alkaline water degreasing – water washing – pickling – water washing – boiling water heating – oxidation – water washing – saponification – self-drying – soaking in hot oil – oil control.

- Phosphating is a process of chemical and electrochemical reaction to form a phosphate chemical conversion film. The formed phosphate conversion film is called a phosphating film.

The process of phosphating: chemical degreasing – washing – pickling – washing – neutralization – washing – (table adjustment) – phosphating – continuous washing – drying or drying – sealing – drying or drying.

03

Surface coating technology of fasteners

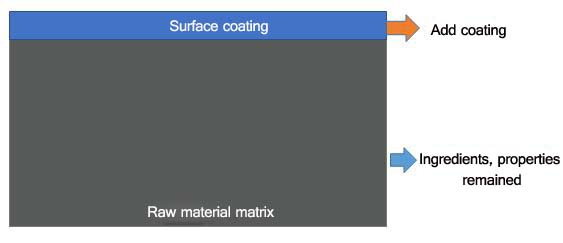

Surface coating technology is also called surface coating (plating) layer technology, that is, through physical and chemical methods, the additive material forms a coating and plating layer on the surface of the substrate.

The substrate does not participate in the formation of the coating.

Electroplating, zinc-aluminum coating and electrophoresis are all surface coatings.

The schematic diagram of the structure principle of the surface coating film is as follows:

1) Electroplating is a process of plating a thin layer of other metals or alloys on certain metals by using the principle of electrolysis, so that a metal film is attached to the surface of metal or other material parts. Commonly used are electro-zinc and electro-zinc-nickel.

1.1 Galvanizing: coating thickness: generally 8-25μm; salt spray test requirements: 72h-240h. Electrogalvanizing is the most commonly used coating for commercial fasteners. It’s cheaper and looks good, and it’s available in silver, army green, black, and colors. However, its anti-corrosion performance is average, and its anti-corrosion performance is the lowest among zinc plating (coating) layers.

1.2 Zinc-plated nickel: coating thickness: generally 8-25μm; salt spray test requirements: 240h-1200h. After color passivation, the zinc-nickel alloy coating can easily pass 1000 hours without white rust under neutral salt spray, while the zinc-nickel coating can pass 120 hours after color passivation. The disadvantage of zinc-nickel alloys is the high cost. Its corrosion resistance is related to nickel content.

Electroplating process: chemical degreasing – water washing – initial electrolytic degreasing – water washing – pickling – water washing – (terminal electrolytic degreasing) – water washing – activation – electroplating – water washing – light (generally only applicable to electro-galvanizing) – water washing – Passivation – washing – sealing – drying.

2) Zinc-aluminum coating (environmentally friendly Dacromet) is an anti-corrosion coating technology that is mainly composed of multi-layer ultra-fine flake zinc, aluminum and inorganic salts, and is cured by a certain temperature and time baking reaction.

Thickness of zinc-aluminum coating: generally 8-25μm; salt spray test requirements: 720h-1500h, with good corrosion resistance, chemical stability and temperature resistance. Torque preload consistent performance is good. There is no hydrogen embrittlement problem, no need for additional dehydrogenation heat treatment, and it is environmentally friendly.

The conductivity of zinc-aluminum coating is not very good, so it is not suitable for parts with conductive connections, such as grounding bolts of electrical appliances.

The technical process of zinc-aluminum coating: organic solvent degreasing – mechanical shot blasting – spraying – baking – secondary spraying – baking – drying.

3) Electrophoretic coating is applied to the cathode and anode, under the action of voltage, the charged paint particles move to the cathode, and act on the alkaline substance generated on the cathode surface to form insoluble matter, which is deposited on the surface of the workpiece.

Coating thickness commonly used in electrophoretic coating: generally 20-40μm, salt spray test requirements: 96h-480h, good anti-corrosion performance, salt spray resistance up to 720h or more. High hardness, strong sense of paint film. It is resistant to discoloration. When baked to 180℃-190℃, the workpiece will not discolor and has strong binding force and penetration force.

Process flow of electrophoretic coating: pre-treatment (methods include pickling, shot blasting, phosphating, electroplating or coating) – electrophoresis – (R/O) water washing – post-treatment sealing (adjustment of friction coefficient) – (R/O) Washed – cured.

04

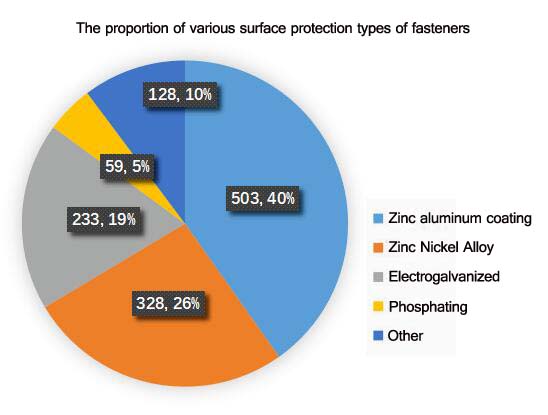

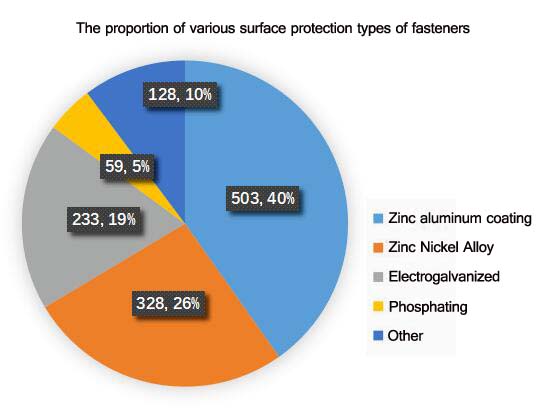

The proportion of various surface treatment types of fasteners

The figure below shows the amount of fasteners and the proportion of various surface protections on a Volkswagen vehicle. It can be seen that the total of zinc-aluminum coating and electroplating is 85%.