Prince Fastener:Fastener production process and crafts– Combined Locking

The fastener production process comprises six major steps: raw material transformation, blank forming, heat treatment, combined locking, surface treatment, and packaging selection.

To solve the problem of anti-loosening of fasteners, bolts and nuts will be used in combination with washers, and nuts will have many types of variants to solve the issues of assembly, anti-loosening, and appearance.

The combination bolt or combination nut is also a kind of bolt and nut, but it is generally a three-component combination.

The assembly, because the flat washer and the spring washer are pre-installed on the bolt or nut, saves the time of manually assembling the flat washer and the spring washer on the final assembly line and improves the assembly efficiency the production line that uses a lot of fasteners.

Non-metallic insert lock nuts, cap nuts with caps, and leaf spring nuts are also threaded assemblies, and different process technologies are used in the factory to produce them.

Prince fastened introduces the fourth article of the fastener production process series, the product types, production processes, and related product standards of fastener combination locking commonly used in fastener production.

01

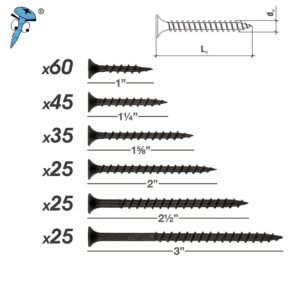

List of types and standards of bolt and screw assemblies

The process production of combined screws is to first cold-pierce the bolts, then put the washers on by hand or with an automatic gasket machine according to the production quantity, and then rub the teeth.

Compared with the manufacture of ordinary screws, there is one more production process and one more method of wearing spring washers and flat washers.

The automatic pad threading machine has three discs, one for screws, one for flat pads, and one for bullet pads. Automatically thread the spring washer and the flat washer and automatically roll the wire.

02 List of types and standards of combined cap nuts

The cap nut is a commonly used standard part. There is a cap on the top of the nut. The function of the cap is to cover the exposed portion of the outer part of the fastening part to prevent moisture or corrosive substances from entering the interior to prevent rust in applications that require aesthetically pleasing fastenings, such as nuts wheel automobiles.

The production process of cap nuts is divided into two types:

One is a one-piece whole, which can be cold-formed, and large-sized products with low output can be red-cut and then cut.

One is a combined type, the nut body and the cap are of separate structures, which are connected by different connection methods. When the split system is adopted, the existing standard nut can be used for the nut body, and the cap of the cold pier only needs to be connected to the nut during processing. This structure reduces the difficulty of manufacturing. There are many process methods for combined connection, and there are also many patented products.

a. The nut body and the cap can be connected by riveting deformation, the sealing performance is poor, there is a particular gap, and the joint is prone to leakage.

b. The combination of the nut body and the cap is most commonly connected by welding, of which butt welding (i.e., butt welding) is a type of resistance welding. It is to heat the connection end of the nut and the cap to a plastic or molten state through an electric current to form a permanent connection under the action of axial pressure.

03

Nuts with washers

The commonly used combined locking method of the nut body and the washer is to machine a small step on the nut, put the washer on, and rivet together with a press. An automatic production line completed them.

04

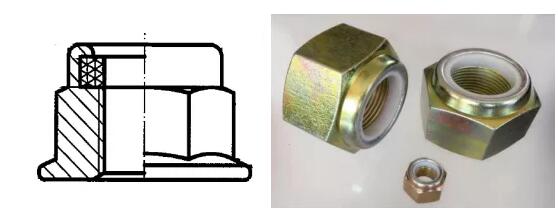

Combination locking of non-metallic insert lock nuts

Reference standards GB/T6182 and GB/T6183.

The non-metallic insert lock nut is a nylon block or a nylon ring whose inner diameter is slightly smaller than the thread diameter in the threaded hole. When the bolt is screwed in, the internal thread is extruded from the nylon ring. The nylon material with excellent elasticity forms a large and stable friction force with the bolt, thereby preventing the loosening of the fastener, achieving reliable locking.

The automatic production line mainly completes the combination locking of the non-metallic insert lock nut; the processed nut body and nylon ring are placed in two vibrating discs, transported by the conveyor belt to the press for automated assembly, and then riveted and sealed. The combined nut is assembled and just assembled.

05

Shrapnel Lock Nuts

The combination locking of the shrapnel-type lock nut and the non-metallic insert lock nuts is similar, and the riveted spring piece and the nut are combined with the press flanging.

06

Cage Nuts

The cage nut can be moved and adjusted within a specific radial range to compensate for the radial tolerance between the connected parts. Nuts are housed in stamped and bent cages.

Today’s topic is shared here. If you have any questions or suggestions, need source files, or need to communicate in the group, you can contact Prince Fastener.