Common quality problems of fastener raw materials

Many reasons lead to quality defects for fasteners. If the causes of these failures and the sources of quality problems are classified, perhaps the most common sense is the quality of raw materials.

Prince Fastener explores some of the most common raw material-related quality issues and explains how each specific issue affects fastener quality.

The raw material is under the enormous pressure of the cold heading machine, which can form complex shapes without bursting or cracking. Therefore, we need raw materials that always maintain performance under extreme conditions, but not all can provide this ideal performance. Therefore, fastener manufacturers must select high-quality cold-formable wire or bar stock.

Typically, further finishing of the stock is required to produce fasteners, including surface cleaning, coating lubrication, annealing to achieve a consistent microstructure, and drawing to improve dimensional and roundness characteristics.

Unfortunately, some quality problems will occur in some places during this process; let’s explore the areas that may go wrong.

crack:

A crack is a product of the casting and rolling process; it may be a small void or depression that is not removed before proceeding; it does not close during rolling but elongates. The depth and length mainly depend on the size of the defect at the origin of the crack and the final diameter of the bar.

Cracks are particularly insidious because they can occur anywhere in the wire and are usually only of short lengths, which means they can be challenging to spot.

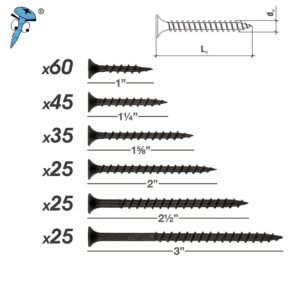

Figure 1 shows a transverse crack in the wire, always running longitudinally to the shaft.

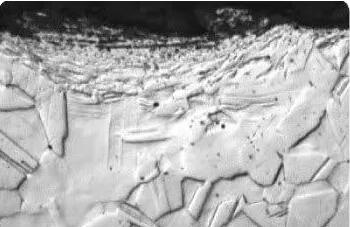

Figure 2 shows a cross-section of the wire with the crack always pointing towards the center.

Folding:

Folds usually appear on the surface of wires and rods, similar to cracks. Sometimes folds are different from damages, irregular, or appear as two parallel lines. The decisive way to identify gaps and folds is to look in cross-section (see Figure 3); cracks always point to the center, while folds can point in any direction.

The folds are produced during the hot rolling process. When the rollers are slightly off course, a small piece of material that will roll off the edge is folded and pressed into the surface as it passes through the subsequent rolling supports. This difference can appear on long sections or even entire wires, unlike cracks, since overlap is usually caused by tool misalignment.

Scratches:

Scratches are the result of mechanical damage during rolling or drawing. If any chips or surface defects are found on the rolling or drawing tool, it can result in a scratched surface.

Also, scratches may look like seams or folds. However, there will be no open gaps like cracks or folds when viewed in cross-sections.

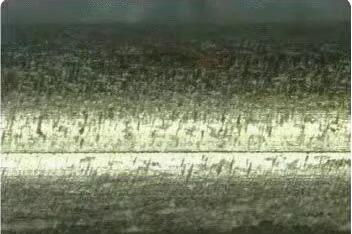

Figure 4 shows the scratches on the cross-section. The material was compressed in the scratched area but not an “open wound.”

Effects of seams, overlaps, and scratches:

In many cases, seams overlaps and scratches have no apparent detrimental effect on the finished product.

However, all three can cause the finished product to crack or burst during the molding process. The most common condition is a cracked head or flange.

Figure 5 shows the defect where the crack leads to the head crack.

Inclusions:

Inclusions are chemical compounds and non-metals present in the steel. While certain non-metallic compounds may be beneficial in some cases, often, the presence of inclusions is detrimental. Even tiny amounts of specific inclusions can dramatically affect the properties of the steel.

Inclusions are generally classified into two categories; external inclusions and bulk inclusions. Bulk inclusions are usually slight in size and are formed by chemical reactions with residual or unstable elements within the metal. External inclusions come from the outside world and are trapped during the melting or casting process. They tend to be residues of slag layers or mold refractories. External inclusions vary widely in size, with large-sized inclusions close to the surface being a hazard for stress concentrations or failure initiation points.

Insufficient lubrication:

One of the necessary conditions for the cold forming process is adequate and effective lubrication at the interface between the raw material and the mold of the formed part. If this lubrication fails, the friction is very high, and the amount will start to stick or “weld” to the working surface of the mold. Parts will be damaged or incompletely formed, and soon the mold will be damaged and fail.

The surface is rough and fouled when the bar comes out of the mill. During machining, it is critical to remove these scales and surface debris. This is usually done by washing the wire rod with hydrochloric acid or sulfuric acid, but it can also be removed using mechanical methods.

After cleaning, a coating must be applied to protect against any subsequent surface erosion and provide the necessary lubrication for forming.

Unreasonable microstructure:

The microstructure is complex, and all of these grains must be aligned to provide optimum performance from the raw material. In particular, grain size, spheroidization (an annealing process of steel), and the number and size of inclusions determine how successfully the wire can undergo the cold forming process.

Prince Fastener’s empirical conclusions:

When there is a problem with the raw material, there will be more significant problems later in the finished part. Under certain conditions, the part function can be predicted based on material properties.

Therefore, fastener manufacturers must be familiar with and understand the raw material suppliers’ fastener manufacturing process quality capabilities and actively cooperate with suppliers to continuously improve the quality performance of raw materials.