Prince Fastener:Fastener production process and crafts– Heat Treatment

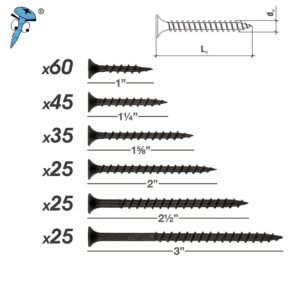

The fastener production process comprises six major steps: raw material transformation, blank forming, heat treatment, combined locking, surface treatment, and packaging selection.

The heat treatment of steel is the four fires often mentioned in heat treatment – annealing, normalizing, quenching, and tempering. It is a process of heating, insulating, and appropriately cooling metal materials or workpieces to obtain the expected structure and properties: method and process.

Among them, quenching and tempering are closely related, and they are often used together and are indispensable.

The main purpose of heat treatment after cold pier forming of fasteners is to obtain good comprehensive mechanical properties of the workpiece through quenching and tempering.

Today, Prince Fastener, the third article in a series of articles on fastener production technology, explains the heat treatment in fastener production, the concepts, and definitions that need to be understood, and introduces commonly used fastener heat treatment parameters and heat treatment equipment – mesh belt furnace.

01 Relevant Concepts of Iron-Carbon Alloy Phase Diagram

The Fe-C alloy phase diagram is the theoretical basis for studying the relationship between the composition, temperature, structure, and properties of iron-carbon alloys and is the basis for formulating the hot working process. Concepts and characteristic lines related to the heat treatment of fasteners:

PSK horizontal line-eutectoid line-A1 line: When the austenite with a carbon content of 0.77% is cooled to this line, a mechanical mixture of ferrite and cementite is simultaneously precipitated at 727 °C. This reaction is called the eutectoid reaction.

GS line-A3 line: The starting line of austenite transformation to ferrite when the steel is cooled.

ES line – Acm line: The solubility line of carbon in austenite is the starting line of precipitation of secondary cementite from austenite during cooling.

Since there is superheat when heating and subcooling when cooling, heating and cooling are different for the same phase transition point. Therefore, when heating, it is represented by c, and when cooling, it is represented by r. Therefore, the corresponding There are heating Ac1, Ac3, Accm, and cooling Ar1, Ar3, Arctic.

Ac1: The starting temperature of pearlite to austenite transformation upon heating.

Ar1: Start temperature of austenite to pearlite transformation on cooling.

Ac3: The final temperature at which free ferrite is completely transformed into austenite during heating.

Ar3: The temperature at which austenite begins to precipitate free ferrite during cooling.

Access: The secondary cementite’s temperature completely dissolves into austenite during heating.

Aram: The temperature at which austenite begins to precipitate secondary cementite during cooling.

The Ac1, Ac3, Accm, and other lines in the iron-carbon balance diagram during heat treatment represent the temperature curve of the transformation of the iron-carbon alloy material. Due to the difference in carbon content, the transformation temperature is different.

02 Quenching

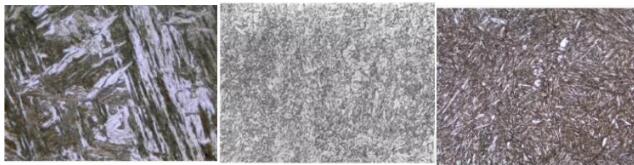

Quenching is a heat treatment process in which the steel is heated to above Ac1 or Ac3, kept for a certain period, and then rapidly cooled to obtain a martensitic structure.

Quenching heating aims to obtain fine and uniform austenite grains to obtain a fine martensite structure after cooling.

Hardenability and hardenability of steel are two key concepts in steel quenching.

The hardenability of steel refers to the ability of the steel to obtain the depth of martensite during quenching. It is the property of the steel itself. It has nothing to do with selecting the furnace type and process. Its size is usually expressed by the depth of the hardened layer obtained by quenching under specified conditions. The hardened layer depth is the vertical distance from the hardened workpiece surface to the specified hardness value.

Hardenability is the ability of a steel to achieve the highest hardness after quenching in the ideal state and depends on the carbon content in the martensite.

Quenching heating temperature and holding time are the keys to quenching.

The quenching heating temperature of hypereutectoid steel is usually 30 to 50°C above Ac3; the quenching heating temperature of hypereutectoid steel is usually 30 to 50°C above Ac1.

When selecting the starting temperature of quenching and cooling, factors such as carbon content, alloying elements, workpiece size and shape, heating method, quenching medium, and original structure should be comprehensively considered.

The holding time includes the heating time of the workpiece in the furnace, the heat penetration time, and the time required for the transformation of the structure. The length of the holding time is related to the furnace load, furnace type, workpiece size, steel composition, and technical requirements.

Commonly used quenching cooling media are water, oil, molten salt, and molten alkali. Common quenching methods include single-liquid quenching, double-liquid quenching, martensitic quenching, and bainite isothermal quenching.

03 Tempered

Tempering is a heat treatment process in which the quenched steel is heated to a temperature below Ac1 and then cooled to room temperature after holding for a certain period.

The purpose of tempering is to eliminate or reduce stress, prevent deformation or cracking; stabilize the structure, stabilize shape and size, ensure accuracy; adjust mechanical properties such as strength, hardness, plasticity, and toughness.

According to the different performance requirements of the workpiece, according to the different tempering temperatures, the tempering can be divided into the following types:

Low-temperature tempering (150-250 degrees), the organization obtained by low-temperature tempering, is tempered martensite. The purpose is to reduce the internal stress and brittleness of the quenched steel while maintaining the high hardness and high wear resistance of the quenched steel to avoid cracking or premature damage during use.

Medium temperature tempering (350-500 degrees), the structure obtained by medium temperature tempering is tempered troostite. Its purpose is to obtain high yield strength, elastic limit, and high toughness.

High-temperature tempering (500-650 degrees), the organization obtained by high-temperature tempering, is tempered sorbate. Combining quenching and high-temperature tempering as quenching and tempering treatment is customary. Its purpose is to obtain comprehensive mechanical properties with good strength, hardness, plasticity, and toughness.

The heat treatment process of fasteners

Quenching and tempering process of fasteners on mesh belt furnace:

04 Mechanical properties and heat treatment process parameters of commonly used fasteners

According to the mechanical properties of the bolts, it is divided into high-strength bolts and ordinary bolts. High-strength bolts mainly refer to bolts with a mechanical property level of ≥8.8.

These products are mainly made of low and medium-carbon alloy (such as boron-manganese or chromium), steel, or medium carbon steel high-quality materials. Except for individual varieties and specifications, they must be quenched and tempered, have high mechanical properties, and Use performance.

Heat treatment is a key process in the production of high-strength bolts, which determines the final performance of the bolts, which can make high-strength fasteners obtain a certain strength, good plasticity, toughness, and low notch sensitivity, as well as high flexural strength and avoidance: comprehensive mechanical properties and service performance such as relaxation phenomenon.

05 Heat Treatment Equipment–Mesh Belt Furnace

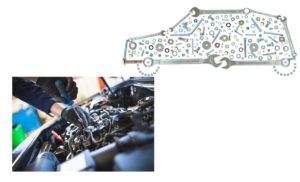

Due to the large production volume and low price of high-strength bolts, and the threaded part is a relatively fine and precise structure, the heat treatment equipment must have a large production capacity, high degree of automation, and good heat treatment quality.

Since the 1990s, the continuous heat treatment production line with a protective atmosphere has dominated, and the shock bottom mesh belt furnace is especially suitable for the heat treatment of small and medium-sized fasteners.

In addition to the good sealing performance of the furnace, the mesh belt furnace production line also has an advanced atmosphere, temperature, computer control process parameters, equipment failure alarm, and display functions.

High-strength fasteners, from feeding-cleaning-heating-quenching-cleaning-tempering-coloring to off-line, are all automatically controlled and operated, which effectively ensures heat treatment quality.

During the quenching and tempering quenching process of fasteners, the main quality problems that may occur are:

Insufficient hardness in the quenched state;

Uneven hardness in the quenched state;

Quenching deformation is out of tolerance;

Quenching cracking.

Common defects after fastener tempering include:

Unqualified tempering hardness;

Temper distortion;

Temper brittleness.

Such problems in the field are often related to raw materials, quenching heating and quenching cooling, tempering temperature, and tempering time. Correctly formulating the heat treatment process and standardizing the production operation process can avoid such quality accidents.